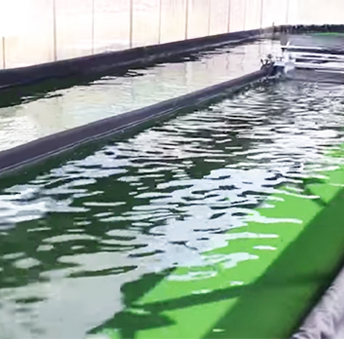

Raceway pond (continuous water circulation), under a greenhouse to maintain a high temperature (35ºC). The intense green color is a sign of a healthy crop with a high concentration of spirulina.

PRESERVE THE

NUTRITIONAL PROPERTIES OF SPIRULINA.

Our will to be producers of spirulina stems from the desire to preserve its numerous nutritional properties in exchange for what has been offered to the consumer to date.

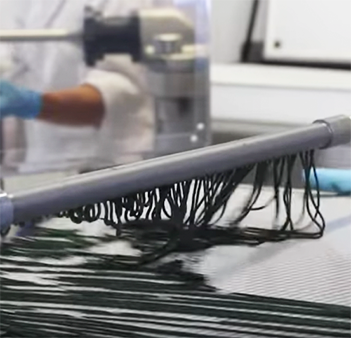

Produced in a protected natural environment (certified by the Serra Calderona Natural Park), surrounded by the orange blossom of the nearby orange trees and with spring water from the Natural Park, we also wanted to control the drying method. It is a fundamental stage to ensure the highest quality of spirulina.

We achieve this thanks to a gentle dehydration of the product, at less than 39ºC, to preserve its nutritional richness.

It is the biggest difference with any industrial spirulina, which is dried at more than 180°C by spray-drying. Dried at such a high temperature, it loses most of its essential nutrients (vitamins, antioxidants, SOD enzyme) and oxidizes. Read more on Spirulina drying method. This type of spirulina represents 99% of the spirulina found on the market. As much as marketing calls them "premium spirulina", "raw food", etc. It is not what we want to propose.

In addition to our objectives, we want to be part of the change in society that we want, with all the transparency that we must demand of our food: our production facilities can be visited between May and October

¡Click here and we will arrange a visit!

It is with a lot of dedication and work that we are carrying out our project, increasingly supported by more people who recognize the quality of the product: we thank you all from the bottom of our hearts. Supporting Ecospirulina is creating employment in Spain, promoting the consumption of quality, fresh, local products, produced with transparency and with respect for the protected natural environment.